Our asbestos inspections include:

(You may choose which services you want included)

WHY QBM for Asbestos Inspections?

QBM provides the most professional asbestos inspections and reporting services at a cost-effective price that reflects the requirements of building owners and managers.

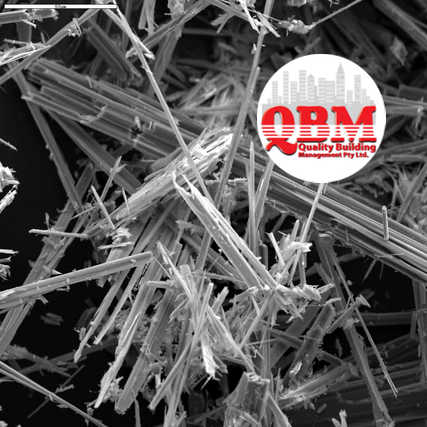

Asbestos Kills!

On average 2 people are diagnosed with mesothelioma each day in Australia (Australian Institute of Health and Welfare)

642 people died from Mesothelioma in 2010. (Safe Work Australia)

701 people diagnosed with mesothelioma each year in Australia since 2011

From 1982 – 2019, the number of new cases of mesothelioma rose from 135 to 532 for males and 22 to 127 for females in Australia

641 people died from Mesothelioma in 2014. (Safe Work Australia)

112 People died from Asbestosis in 2010 (Safe Work Australia)

An additional 40,000 Australians will be diagnosed over the next 17 years (Bill Shorten 2013)

The majority of buildings constructed < 1990, and most plant and equipment < 2004 will contain asbestos. But Australia is still importing sheeting containing asbestos.

THE LEGISLATION

Work Health and Safety Legislation in all Australian States and Territories legislate that all building owners and managers must undertake asbestos inspections to identify the presence, condition and health effects of all asbestos in their buildings.

The person with management or control (Owners and managers of all buildings) (not detached houses) constructed < 2004 must identify and report on all asbestos within those buildings. However, China is exporting building products to Australia containing asbestos due to lax controls. Therefore, although not required by legislation, buildings constructed up to today may in fact contain asbestos.

Where asbestos is identified a Register must be developed and a Management Plan developed.

Queensland Variation:

An Asbestos Inspection must be undertaken to identify if asbestos is present in all buildings (not residential), but an asbestos register is not required if the building was constructed > 1990 and does not have any asbestos on site. You still need to inspect the building to prove that asbestos is not present.

WHAT IS A WORKPLACE?

A workplace is anywhere that work can be undertaken.

A place where work is being undertaken is a workplace.